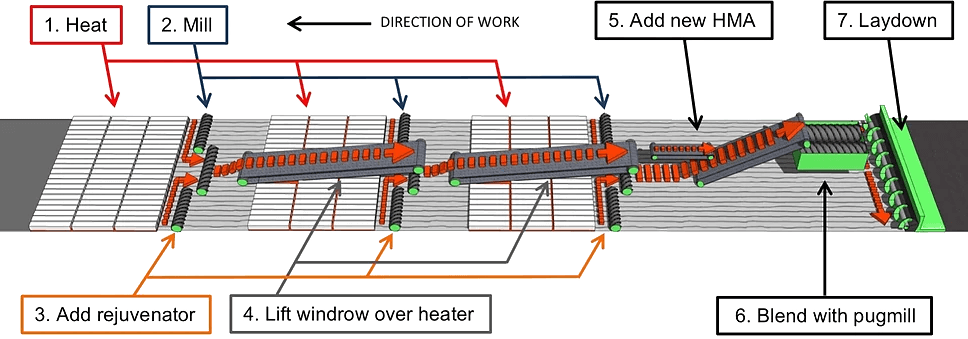

Technology

Enabled by our unique Multi-Stage Hot Milling process the Ecopaver 400 can heat, remove, rejuvenate and relay asphalt to a depth of 50 mm at up to 4 lane kilometers per day. A rejuvenating agent is added to restore binder properties and up to 30% new HMA can be added to improve gradation and correct loss of profile due to dips, ruts and potholes.

How it works

- Radiant heat is applied to the surface to liquefy the binder.

- Rotary cutters mill a portion of the desired depth and windrow it to the center.

- Rejuvenating agents are added to restore binder properties.

- A conveyor lifts the windrow over the next heater, exposing the lower layer for additional heating.

- The above steps are repeated two or three times depending on system configuration.

- New HMA is added to modify the aggregate gradation and improve smoothness.

- The final steps are lay down and compaction using conventional equipment and methods.